Model No.: 53m Aerial Platform Firefighting Vehicle

Chassis brand: 6X4 MAZ

Firefighting Pump: Not included (Installation reserved)

Firefighting Monitor: US Akron PLKD10/80B-5177 (made in Germany)

Boom: 5 sections of telescopic boom+1 section of articulating boom + 1 section of fly boom

Outrigger: H type with auto-extend and retraction function

Hydraulic system: Proportional valve load sensitive system

|

|

|

|

Description

BRIEF

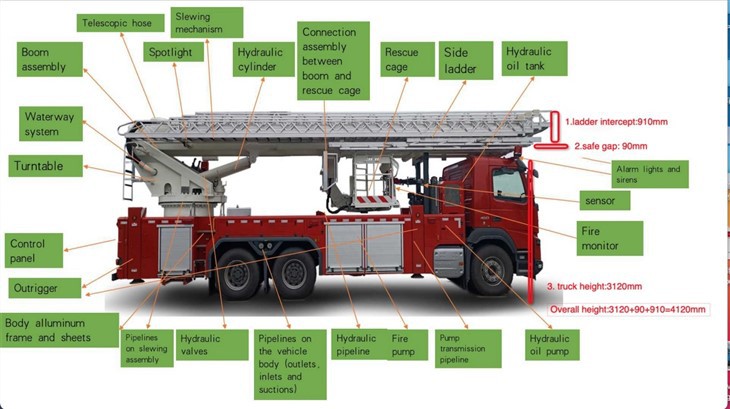

The 53m Aerial Platform Firefighting Vehicle represents a cutting-edge innovation in fire rescue technology, blending the robust MAZ chassis with a meticulously crafted superstructure manufactured in CSCTRUCK. This fusion of engineering prowess results in a formidable firefighting apparatus, equipped with state-of-the-art features and capabilities to combat fires efficiently and effectively.

One of the standout features of this vehicle is its fully upgraded design, which encompasses various aspects including the form, structure, and functionality. The combination of booms, meticulously engineered boom sections, and long-span outriggers contribute to its exceptional performance and versatility in diverse firefighting scenarios. This amalgamation of advanced engineering ensures that the truck can navigate challenging terrains and reach otherwise inaccessible areas with ease.

With a maximum working height of 53 meters, this aerial platform offers unparalleled reach, allowing firefighters to tackle fires in high-rise buildings and other elevated structures with confidence. Additionally, the vehicle boasts an impressive maximum working outreach of 400kg at 19 meters and 22 meters when unloaded, further enhancing its firefighting capabilities across a wide range of scenarios.

Despite its formidable capabilities, the 53m Aerial Platform Firefighting Vehicle maintains a manageable weight, with a full load weight of 32,000kg. This optimal balance between performance and weight ensures agility and maneuverability during operations, enabling firefighters to respond swiftly to emergencies without compromising on safety or efficiency.

In essence, the 53m Aerial Platform Firefighting Vehicle represents the pinnacle of aerial firefighting technology, embodying innovation, reliability, and efficiency. Its advanced features and robust construction make it an indispensable asset in modern firefighting fleets, capable of safeguarding lives and property against the destructive force of fires in the most demanding of circumstances.

FEATURES

1) Long-span combination booms boast exceptional over-leaping capacity for high obstacles, facilitated by telescopic booms, 2 telescopic crankshafts, and 1 jib. With a working scale extending up to 23 meters and the ability to clear obstacles up to 10.5 meters, they excel in long-span operations.

2) This 53m Aerial Platform Firefighting Vehicle offers impressive mobility and passage capacity, with a maximum drive length of 12 meters and a height not exceeding 4 meters. These dimensions represent the lowest among similar domestic products, enhancing its maneuverability significantly.

3) With its multi-curve design, heavy load capacity, and high efficiency, this equipment demonstrates formidable rescue capabilities. It can operate up to 23 meters under a 500kg load and 25 meters under a 320kg load, marking a 25% improvement in maximum working load compared to state-of-the-art standards.

4) Exceptional fire performance characterizes this equipment, designed to be lightweight for optimal load distribution. With a full-load weight of 3,400kg water and 2,000kg foam, it achieves a flow rate of 64L/s, the highest level among similar products. Its capability to function as a high-flow spray engine further underscores its firefighting prowess.

SPECIFICATION

|

Overview |

|

|

Chassis |

MAZ |

|

Driving type |

6×4 maz |

|

Fire pump |

Not included (Installation reserved) |

|

Fire monitor |

US Akron PLKD10/80B-5177 (made in Germany) |

|

Boom |

5 sections of telescopic boom+1 section of articulating boom + 1 section of fly boom. |

|

Outrigger |

H type with auto-extend and retraction function. |

|

Hydraulic system |

Proportional valve load-sensitive system. |

|

Control System |

CAN BUS intelligent control system. |

|

Waterway System |

Aluminum alloy hard pipe and telescopic water pipe + rubber-lined spiral steel hose. |

|

The body |

Lightweight anti-corrosion, anodized all-aluminum alloy frame + aluminum sheet cover. |

|

Main Technical Parameter |

|

|

Overall Dimensions |

|

|

LxWxH |

11,900×2,530×3,995mm |

|

Outrigger span (Vertical+horizontal) |

7,100×5,500mm |

|

Max working height |

53m |

|

Max working outreach |

400Kg-19m, Unloaded-22m |

|

Cradle rated capacity |

400kg |

|

Boom lifting time |

≤150s |

|

Boom restricting time |

≤220s |

|

Outrigger leveling time |

≤40s |

|

Max wind speed allowed |

12.5 (level 6) m/s |

|

Driving and Power Parameter |

|

|

Full load weight |

≤32,000kg |

|

Engine power |

Refer to MAZ |

|

Cab seat |

2 people |

|

Emission standard |

Refer to MAZ |

|

Firefighting System |

|

|

Max flow on fire pump |

5,[email protected] L/min@MPa |

|

Max flow@max working height |

4,[email protected] L/min@MPa |

|

Max flow on fire monitor |

4,[email protected] L/min@MPa |

|

Water tank |

/ |

|

Rated spraying reach on fire monitor |

65m |

|

Max firefighting radius |

90m |

|

Rotation angle of fire monitor |

-46~+64° |

|

The pitching angle of the fire monitor |

-46~+46° |

|

Superstructure |

|

|

Cradle rated capacity |

400kg Not spraying condition, 150kg Spraying condition. |

|

Platform area |

≥1.6m2 |

|

Leveling method |

The electro-hydraulic intelligent independent leveling system. |

|

Self-protection spraying flow |

≥284L/min |

|

No. of boom |

5 sections of main boom +1 section of articulating telescopic boom +1 section of fly boom. |

|

Boom material |

High-strength steel. |

|

Telescopic mechanism |

Telescopic cylinder + steel rope. |

|

Boom operation mode |

Foot pedal + handle step-less control; manual forced operation. |

|

Turntable |

Integrated control type, 360° unrestricted rotation. |

|

Outrigger |

|

|

Type |

H type with single cylinder |

|

Span |

100mm (Vertiacal) x 5500mm(horizontal) |

|

Outrigger operation mode |

Auto-extend and retraction; Electronic control + manual; Manual forced. |

|

Side Ladder |

|

|

General structure |

Side ladder on the turntable 5 sections of the telescopic ladder on the main boom + 1 section on the articulating boom. |

|

Side ladder material |

High-strength anti-rust aluminum alloy. |

|

Telescopic |

Synchronized telescoping with the main boom. |

|

Waterway System |

|

|

Fire pump model |

US Akron PLKD10/80B-5177 (made in Germany). |

|

Max flow of fire monitor |

|

|

Fire monitor mode |

Electric control of the fire monitor can realize the action of horizontal rotation, pitch with smooth bore, and fog spraying mode. |

|

Telescopic pipe |

Aluminum alloy telescopic pipe. |

|

Other pipes |

Stainless steel, aluminum alloy, rubber-lined spiral steel hose. |

|

Electrical System |

|

|

Control system |

CAN BUS intelligent control system (controller + display screen + control program) |

|

Consoles |

Turntable console (with seat) Cradle console Console at the rear of the vehicle. |

|

Intercom system |

Non-handheld wired intercom system between turntable and cradle. |

|

Automatic disconnect charging device |

The battery can be charged with 220V mains power, and the charging plug will automatically detach when the vehicle startup. |

|

Reversing assist system |

With a reversing alarm buzzer, reversing camera, and cab monitor. |

|

Cradle overload protection |

When the cradle exceeds the rated load, the system will alarm and cut off all actions. |

|

Cradle tilt-over protection |

When the cradle tilts more than 7°, cut off all actions. |

|

Cradle anti-collision protection |

When the cradle approaches the obstacle, the system alarms and stops the dangerous direction from continuing to approach. |

|

Boom buffer protection |

In case of limited position or suddenly touching the handle, the system will accelerate automatically or decelerate smoothly. |

|

Boom limiting protection |

The boom will automatically stop slowly when it is close to the limit range. |

|

Rotation limit protection |

When the boom turns to the short outrigger, it will cut off the turning action in a dangerous direction. |

|

Self-lowering function |

When all power fails, the boom will rely on gravity to lower the telescopic boom and the main boom slowly. |

|

Rotary alignment |

When the rotation is close to the middle, the boom will reduce the movement speed automatically to ensure accurate center alignment. |

|

Body anti-collision |

To prevent the boom from colliding with the car body, when the ladder frame turns to a certain position, it will automatically stop the dangerous direction of turning. |

|

Interlock |

The outriggers must be extended for the boom to operate; the outriggers cannot operate when the boom has extended. |

|

Emergency function |

The operating hydraulic valve and outriggers operating valve have the function of emergency manual operation; The system with an emergency power unit for winding up the ladder and outriggers in case of engine or oil pump failure. |

|

Outrigger operation alarm |

When the outrigger is in operation, the protection system will light and alarm automatically. |

|

Protection for outrigger unstable |

When the boom is under operation, the protection system will stop the dangerous direction automatically if any of the outriggers are not stable. |

|

Outrigger retraction reminding |

If the outriggers are not properly retracted, an automatic alarm will sound to prevent accidents during the operation. |

|

Engine speed protection |

The engine speed is automatically restricted when the boom is in motion. Additionally, when the water pump is operating, measures are taken to prevent water system overpressure or pump overspeed with automatic engine speed limitation. |

|

Over wind speed alarm |

When the wind speed exceeds 12.5m/s, the system will alarm and stop the dangerous operation automatically. |

|

Reminding for the unclosed door of the equipment box |

The light will automatically alarm if the equipment door is not closed. |

|

Filter block protection |

When the filter is blocked, the alarming light will on. |

|

Hydraulic oil over temperature protection |

If the hydraulic oil temperature is too high, the system will automatically start the radiator to reduce the temperature. |

|

Maximum system pressure |

23Mpa |

|

Hydraulic System |

|

|

Outrigger valve |

High-quality brand, electromagnetic proportional valve. When the outrigger operates automatically, the engine speed will increase automatically. |

|

Balance valve another core valve |

High-quality brand. |

|

Emergency Power Unit |

Gasoline engine drive. |

|

Hydraulic oil specification |

Common area and cold area: Great wall low temperature 32. Extremely cold area: Kunlun No. 10 ground aviation hydraulic oil. |

|

Body |

|

|

General description |

The body uses a variety of high-strength special aluminum profile lap joint skeletons, and the turnover door is lightweight, heavy bearing, and has good anti-corrosive performance. Applied with aerospace adhesive on aluminum sheets to ensure high bonding strength, vibration, and noise reduction. |

|

Structure |

The body frame is constructed by high high-strength aluminum alloy profile with hidden lap joint technology. The body aluminum sheet cover is bonded with high-strength structure adhesive. |

Hot Tags: 53m aerial platform firefighting vehicle, China, manufacturers, suppliers, factory, price, quotation, for sale, high quality, high performance

FAQs

Q: Are you a trading company or a manufacturing factory?

A: We are both. We have operated our own factory for over a decade and recently established a trading company to better serve our overseas customers. We welcome your inquiries and factory visits.

Q: What is your typical delivery time?

A: Our delivery time usually ranges from 20 to 50 days after receiving the advance payment. The exact timeline depends on the specific items and quantities in your order.

Q: How do you ensure product quality?

A: We maintain strict quality control standards through our ISO9001:2008 certified system. Additionally, our professional Quality Control team conducts thorough inspections to guarantee the excellence of our products.

Q: What are your payment terms?

A: We require a 40% deposit via T/T (Telegraphic Transfer), with the remaining 60% due before delivery. We will provide photos of the products and packaging for your approval before the final payment.

How are your trucks shipped?

A: Large trucks are typically shipped via RORO (Roll-On/Roll-Off) or bulk cargo ships. Smaller vehicles can be transported in containers. Please contact us for a detailed shipping quotation.

Q: Do you offer customized products?

A: Absolutely. We can design and manufacture customized products to meet your specific requirements.

Q: What kind of after-sales service do you provide?

A: We offer a five-year warranty on our products, covering manufacturing defects. If any quality issues arise within this period, we will repair or replace the product at our expense. For issues outside the warranty coverage, we provide after-sales service at the customer’s expense.