5,000L Water Tank and 10CBM Sludge Tank

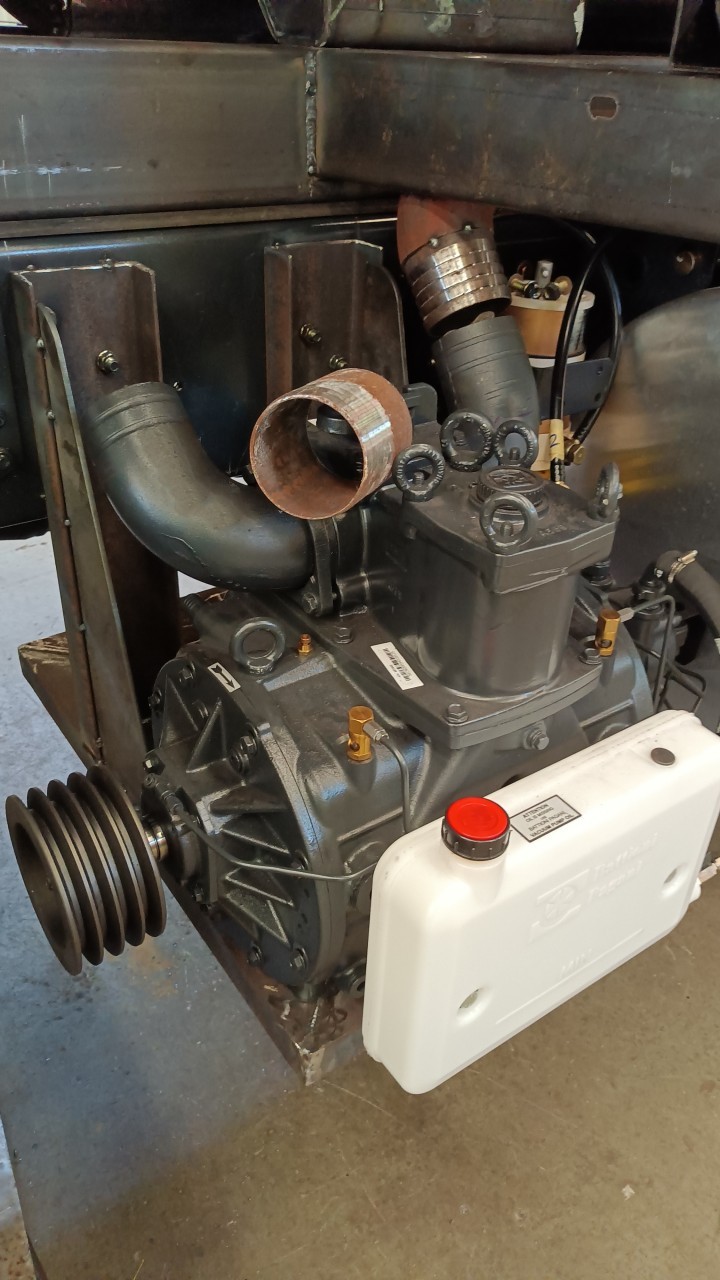

Battioni Pagoni Vacuum Pump

15,270L/min Flow Capacity

USA UDOR Jetting Pump

SAIC-IVECO Hongyan 6×4 Truck Chassis

290ps Diesel Engine

FAST™ 12F+2R Speed Manual Transmission

|

|

|

|

Description

BRIEF

The combined sewer truck stands as a specialized marvel in the realm of pipe and channel maintenance, seamlessly integrating dredging, cleaning, and sewage suction functionalities. Crafted with precision, this vehicle incorporates professional manufacturing techniques derived from both European and American expertise, enriched further by the meticulous craftsmanship of the skilled “CSCTRUCK” artisans. The result is a vehicle that transcends ordinary standards, delivering a harmonious blend of form and function.

Infused with a comprehensive set of features, the combined sewer truck boasts versatility, operating at high pressure with ample flow, formidable suction lift capabilities, and an impressive level of automation. This amalgamation of attributes translates into a significant enhancement of overall work efficiency, offering a solution that meets the demands of modern pipe and channel maintenance with unparalleled finesse.

What sets this vehicle apart is its adherence to advanced manufacturing methodologies borrowed from international standards, coupled with the artistry of dedicated craftsmen. The infusion of European and American technologies elevates the vehicle’s capabilities, ensuring it meets the rigorous demands of the industry. The meticulous attention to detail by “CSCTRUCK” craftsmen ensures that each unit is not merely a vehicle but a carefully curated piece of engineering excellence.

In essence, the combined sewer truck stands as a testament to the symbiosis of cutting-edge technology and artisanal craftsmanship. Its full-spectrum functionality, formidable pressure, abundant flow capacity, remarkable suction capabilities, and advanced automation collectively position it as a transformative force in the landscape of pipe and channel maintenance, setting a new standard for efficiency and effectiveness.

FEATURES

- Imported high-pressure pumps and vacuum pumps from the original brand not only fulfill the requirements for high water pressure and substantial flow in cleaning tasks but also boast significant displacement and exceptional suction capacity.

- In the event of a low water level in the clean water tank, an automatic alarm is triggered, leading to a reduction in engine speed. The water outlet pipe is adjusted to the water return state, effectively preventing damage caused by a shortage of water in the high-pressure pump.

- Several protective measures, including a sludge filling alarm, primary check valve, secondary check valve, and air intake filtration, form a multi-level protection system that safeguards the vacuum pump from damage due to flooding.

- The high-pressure hoses can be hydraulically retracted and extended to reduce labor intensity and enhance work efficiency. The speed of retraction and extension can be instantly adjusted based on work requirements, and the length of extension and retraction can be accurately recorded.

SPECIFICATION

|

Chassis |

|

|

Size |

10,100 x 2,500 x 3,850 (mm) |

|

GVW/Curb Weight |

39,500/12,500kg |

|

Wheelbase |

3,800+1,350+1,350mm |

|

Front/Rear Axle |

7.5T/16T/16T |

|

Tire |

12.00R20 10+1 tires |

|

Engine |

|

|

Type |

Diesel |

|

Make/Model |

Cursor9/C9 290/290hp/ Euro 5 |

|

Transmission |

|

|

Model |

FAST |

|

Gears |

12F+2R |

|

Operation |

Manual |

|

Cabin |

|

|

Driving |

SAIC-IVECO Hongyan, Flat Roof Short Cab with Sleeper, Left Hand Drive. |

|

Type |

Steel construction, Single Row, Flat. |

|

Passenger No. |

3 |

|

Tank Equipment |

|

|

Tipping |

The tank is mounted with an arrangement for rear tipping. |

|

Total Internal Volume |

15,000liters |

|

Material |

The tank is made of 6mm steel ASTM-A 36 or equivalent material. |

|

Thickness |

Dish end/portions are made of 6mm thickness ASTM-A 36. |

|

Division of Compartment |

The tank is divided into two compartments. Cleaning water tank compartment: 5,000liters Sludge/sewage tank compartment: 10,000 liters. |

|

Rear Door Locking and Opening |

Rear door locking and opening are done hydraulically. |

|

Discharge Spill Way |

Mounted to the rear side of the sludge tank to keep the bumper clean. |

|

Baffle Plates |

Provided to avoid surge mass during vehicle movement. |

|

Manhole |

450 in diameter located at the top of the sludge tank. |

|

Water Inlet and Outlet |

Water inlet and outlet 2 1/2’’ with manual valve and coupling. |

|

Sludge Suction |

Manually controlled gate type with 4’’ suction valve with quick coupling. |

|

Sludge Discharge |

Manually controlled gate type with 6’’ suction valve with quick coupling. |

|

Sight Glass |

The tank is provided with 3 units of sight glass located at the end dish of the tank to measure the volume of sewage inside the tank. Sight glass is tempered-proof material and is easily replaced. |

|

Vacuum Pump |

|

|

Make/Model |

Battioni Pagoni/KPS-B 550 |

|

Type |

Water-cooled vacuum pump, heavy duty/multi-cylinder type, strong high-pressure, continuous duty. It is fitted with a rotary sliding vane, positive displacement type exhauster/compressor. |

|

Air Capacity |

15,270Lt/min |

|

Rotor Speed |

1,400rpm |

|

Max. Vacuum |

95% |

|

Drive Type |

The vacuum pump can be driven by the auxiliary engine, but we advise installing the new generation split shaft P-T-O which can drive the vacuum pump and jetting pump. |

|

Tank Fittings/Safety Measures |

|

|

Anti-flow devices |

Primary Shut-off and Secondary Shut-off. |

|

Safety |

1.5’’ Vacuum Relief Valve and 2’’ Pressure Relief Valve. |

|

Vacuum/Pressure Gauge |

4’’ vacuum/pressure gauge. |

|

Suction filter, Silencer |

Installed. |

|

High-Pressure Jetting Pump |

|

|

Make/Model |

UDOR/VX-B100/200R |

|

Origin |

USA |

|

Type |

Heavy-duty positive displacement single-acting triplex reciprocating pump to be driven by a power take-off unit. |

|

Max. Flow |

100l/min |

|

Max. Pressure |

200 Bar |

|

Drive Type |

Drive for the high-pressure jetting pump, as also the vacuum pump is tapped from a new generation total power take-off (split shaft P.T.O.). |

|

Safety |

Drive for the high-pressure jetting pump, as also the vacuum pump is tapped from a new generation total power take-off (split shaft P.T.O.). |

|

Hose Reel |

|

|

Main Hose Reel |

Rear mounted hose reel DN1’’ 100~150m length. |

|

Auxiliary Hose Reel |

Provided at the rear side of the truck chassis, manual hose reel 1/2’’ 60m textile braid reinforcement type with coupling for cleaning nozzles. |

|

Control System |

|

|

Type |

The system is driven by a control panel fixed on the backside of the tank and a remote control for the boom system. All controls for the operation and the workings of the truck are fitted to an illuminated, lockable, water-resistant control panel that is attached and moves with the hose reel. |

Hot Tags: iveco 6×4 combined sewer truck, China, manufacturers, suppliers, factory, price, quotation, for sale, high quality, high performance

FAQs

Q: Are you a trading company or a manufacturing factory?

A: We are both. We have operated our own factory for over a decade and recently established a trading company to better serve our overseas customers. We welcome your inquiries and factory visits.

Q: What is your typical delivery time?

A: Our delivery time usually ranges from 20 to 50 days after receiving the advance payment. The exact timeline depends on the specific items and quantities in your order.

Q: How do you ensure product quality?

A: We maintain strict quality control standards through our ISO9001:2008 certified system. Additionally, our professional Quality Control team conducts thorough inspections to guarantee the excellence of our products.

Q: What are your payment terms?

A: We require a 40% deposit via T/T (Telegraphic Transfer), with the remaining 60% due before delivery. We will provide photos of the products and packaging for your approval before the final payment.

How are your trucks shipped?

A: Large trucks are typically shipped via RORO (Roll-On/Roll-Off) or bulk cargo ships. Smaller vehicles can be transported in containers. Please contact us for a detailed shipping quotation.

Q: Do you offer customized products?

A: Absolutely. We can design and manufacture customized products to meet your specific requirements.

Q: What kind of after-sales service do you provide?

A: We offer a five-year warranty on our products, covering manufacturing defects. If any quality issues arise within this period, we will repair or replace the product at our expense. For issues outside the warranty coverage, we provide after-sales service at the customer’s expense.