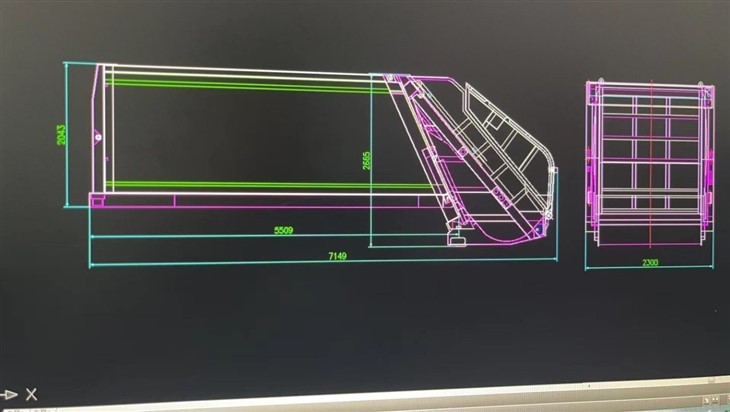

Make&Model: CSCTRUCK/GC14

Overall Dimension(L x W x H): 7,14×2,300×2,043 mm

Gross Body Weight: 6,000kg

Garbage Container Capacity: 14m³

|

|

|

|

Description

BRIEF

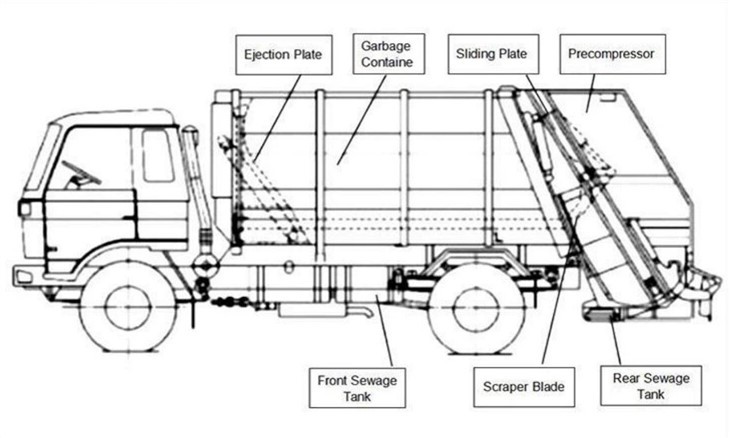

The compactor garbage body system is a cutting-edge waste management solution designed to be mounted on various truck chassis brands. It comprises a robust sub-frame that is securely connected by a U-bolt mechanism, ensuring stability and efficient waste handling during transportation.

Within the garbage compactor body, a series of essential components work seamlessly together to manage waste effectively. The heart of the system is the sealed tank, providing a contained environment to handle the diverse types of waste efficiently and hygienically. This ensures that no leakage or spillage occurs during the collection and transportation process, promoting a clean and eco-friendly operation.

The system’s functionality is further enhanced by the inclusion of several vital elements. The ejection plate, sliding plate, and scraper play pivotal roles in the waste compression process. When refuse is thrown into the body, the press plate initiates the crushing stage, reducing the volume of the waste. Subsequently, the ejection plate takes over, further compressing and compacting the waste within the body. This ingenious design allows for greater waste capacity, reducing the frequency of trips needed for disposal, and minimizing fuel consumption and greenhouse gas emissions.

To ensure smooth operations and precise control, a sophisticated hydraulic system is integrated into the garbage compactor body. The hydraulic system efficiently powers the movements of the press plate and ejection plate, providing the necessary force for waste compaction and discharge. This dynamic hydraulic mechanism optimizes waste handling, ensuring a quick and reliable waste management process.

Overall, the compactor garbage body system offers a comprehensive waste management solution that improves the efficiency of waste collection and transportation. By implementing advanced technology and durable materials, this system contributes to cleaner cities and a healthier environment. Its innovative design, featuring the sealed tank, press plate, ejection plate, and hydraulic system, guarantees a seamless waste compaction process, making it an invaluable asset for waste management companies and municipalities alike.

FEATURES

1. The Compactor Garbage Body comprises various components, including a sealed garbage container, ejection plate, slide plate (guide rail), sweeper shovel, hopper, lifting device, sewage tank, hydraulic system, and control system.

2. The process begins with loose garbage in the hopper, which is directed into the body by a sweeper shovel activated by two double-acting hydraulic cylinders. Subsequently, two double-acting sled cylinders push the waste further into the body. To discharge the refuse, the ejection plate is employed to push it out of the body.

SPECIFICATION

|

1) General Information |

|

|

1.1 Make & Model |

CSCTRUCK / GC14 |

|

1.2 Date of Manufacturing |

2023 |

|

1.3 Country of Origin |

China |

|

1.4 Truck Unit’s Status |

Brand new |

|

1.5 Overall Dimension (L x W x H) |

7,149×2,300×2,043 mm |

|

1.6 Gross Body Weight |

6,000kg |

|

1.7 Garbage Container Capacity |

14m³ |

|

2) Body and Compaction System |

|

|

2.1 Tank |

Tank floor NM450 (similar to HARDOX) wear-resistant steel; Sidewall and roof are fabricated with corrosion resistance Q235 carbon steel (equivalent as IS-2062 Grade A or ASTM a36) Body floor: 5 mm Body side: 4 mm Body roof: 4 mm |

|

2.2 Hopper Floor |

NM450 (similar to HARDOX) wear-resistant steel Thickness: 6mm |

|

2.3 Hopper Cylinder

|

Reinforced external cylinder, maintenance-free. High-precision, sealing rings are imported parts, with no oil leakage, pressure instability, or other problems. Blasting and anti-dust painting. Multi-stage cylinder for push function: 1pcs Cylinder for strickle function: 2pcs Cylinder for slide function: 2pcs Cylinder for lifters: 2pcs Cylinder for rear cover: 2pcs |

|

2.4 Compression Ratio

|

The advanced hydraulic system, the pilot-type back pressure design, and the peristaltic compression technology are used, which greatly improves the compression capacity. |

|

2.5 Slide Assembly |

The slide assembly adopts the laser cutting process, the steel castings are integrally formed, and the main structural steel plates are thickened, the thickness reaches 20mm, and the performance is higher than the products in the same industry. |

|

3) Lifting Devices |

|

|

3.1 Working Principal |

High capacity articulated arm lifting device works in two stages by four double effects hydraulic cylinders to ensure the lifting and lowering of containers smoothly. |

|

3.2 Hydraulic Cylinder |

The tailgate cylinder is externally reinforced, and the maintenance is convenient. Adopting top brands, stable quality, durable, high pressure, and fast cycle speed. |

|

3.3 Hydraulic Pipe |

Adopts precision seamless cold-formed hydraulic oil pipe, which can prevent overheating and deformation, and has a longer service life. |

|

3.4 Balance Valve |

Ensure the stability and safety of oil cylinder operation, prevent the cylinder from falling due to operational errors, and eliminate potential safety hazards. |

|

3.5 Lifting Device |

Available to lift standard 120/240/770 and 1100 liter. steel and plastic containers. Lifting weight capacity not less than 800 kg (All lifting device arms and parts are made of High Strength Steel). |

|

4) Control System |

|

|

4.1 Working Principal |

The system is controlled from the manual control system, which enables, start, stop, 1-cycle, continuous cycles, and rescue activities. Tailgate and ejector controls are in front of the body. All devices for loading control are mounted on the tailgate right side, and all are manual control for safety purposes. Compaction is controlled electrically via push-buttons, and manually in case. There is an emergency stop button on each of side the truck on the control panel. |

|

4.2 Hydraulic Control Valve |

It is the core component of the control system, and all hydraulic cylinder actions must be regulated through this valve group. The hydraulic control valve has fine workmanship and small size. The valve stem is made of 40Gr material, which has high precision and wear resistance. At the same time, a 3+2 mode valve can be selected according to the needs of customers. It avoids damage to the vehicle structure and hydraulic system caused by some actions due to excessive speed. |

|

4.3 Electric Control Box |

The automatic control unit, compared with the previous electronic control, is waterproof, and more convenient to use. With the multi-function operation of a garbage truck. |

|

4.4 In-cab Control |

In-cab smart control the unloading, and safety operation. |

|

5) Painting / Finishing |

|

|

5.1 Both Painted |

The exterior and interior of the tank are spray painted with high-quality painting |

|

5.2 Exterior |

Spray-painted with two coats of superior quality anti-corrosive primer and two coats of enamel metal paint of a reputed make. (Color/Logo/Mark are customized) |

|

6) Included |

|

|

6.1 All Accessories |

Body structure 1 set Tailgate assembly 1set Press plate assembly 1 set Ejection plate assembly 1 set Lifting device 1 set Waste water tank 1 set – Multi-way valve 1 set – Hydraulic cylinders 9pcs – Oil Pump 1 set – Hydraulic Oil Tank 1 set – Hydraulic Hoses – Balance Valve 2 sets – Control system |

FAQs

Q: Are you a trading company or a manufacturing factory?

A: We are both. We have operated our own factory for over a decade and recently established a trading company to better serve our overseas customers. We welcome your inquiries and factory visits.

Q: What is your typical delivery time?

A: Our delivery time usually ranges from 20 to 50 days after receiving the advance payment. The exact timeline depends on the specific items and quantities in your order.

Q: How do you ensure product quality?

A: We maintain strict quality control standards through our ISO9001:2008 certified system. Additionally, our professional Quality Control team conducts thorough inspections to guarantee the excellence of our products.

Q: What are your payment terms?

A: We require a 40% deposit via T/T (Telegraphic Transfer), with the remaining 60% due before delivery. We will provide photos of the products and packaging for your approval before the final payment.

How are your trucks shipped?

A: Large trucks are typically shipped via RORO (Roll-On/Roll-Off) or bulk cargo ships. Smaller vehicles can be transported in containers. Please contact us for a detailed shipping quotation.

Q: Do you offer customized products?

A: Absolutely. We can design and manufacture customized products to meet your specific requirements.

Q: What kind of after-sales service do you provide?

A: We offer a five-year warranty on our products, covering manufacturing defects. If any quality issues arise within this period, we will repair or replace the product at our expense. For issues outside the warranty coverage, we provide after-sales service at the customer’s expense.