Brand/Model: CSCTRUCK/CSC5340GJJ

Overall Dimension(LxWxH): 11,460×2,500×3,300mm(approx.)

Max. Speed: 30km/h

Drive Type: LHD

Fuel Tank Capacity: 25,000Liters

Tank Material: Aluminum alloy

Refueling Flow Rate of Single Reel Hoses: 1,200L/min

Flow Rate for Defiling Oil/Pumping of Single Reel Hoses: 300L/min

Flow Rate of Loading Oil: 1,500L/min(single hose)2,500L/min(double hoses)

Centrifugal Pump Brand: Gorman Rupp

Pressure Control Valve: Maggitt or Alfons Haar

|

|

|

|

Description

BRIEF

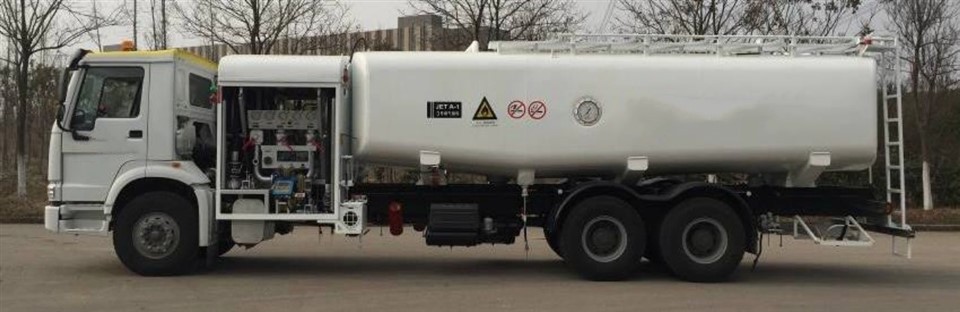

The ISUZU 25,000-liter aircraft refueling truck, produced by CSCTRUCK, is a high-capacity, specialized vehicle designed for efficient and reliable aircraft refueling operations. Built on a robust ISUZU chassis, this truck is engineered to meet the demanding requirements of aviation fuel handling with a focus on safety, durability, and performance.

The truck features a 25,000-liter aluminum alloy fuel tank, which is both lightweight and corrosion-resistant, ensuring long-term reliability. The vehicle is equipped with advanced fuel handling systems, including a Gorman Rupp centrifugal pump that guarantees efficient fuel transfer. The refueling process is facilitated by single reel hoses, capable of delivering fuel at a rate of 1,200 liters per minute while refueling or pumping is managed at a rate of 300 liters per minute.

For loading operations, the aircraft refueling truck offers impressive flow rates of 1,500 liters per minute using a single hose or 2,500 liters per minute with double hoses. To ensure precise fuel flow and safety, the truck is fitted with high-quality Maggitt or Alfons Haar pressure control valves.

Despite its substantial fuel capacity, the truck maintains a manageable maximum speed of 30km/h, making it ideal for safe maneuvering in airport environments. This ISUZU aircraft refueling truck by CSCTRUCK represents a sophisticated and reliable solution for airports and aviation companies requiring efficient, high-volume refueling capabilities.

FEATURES

– Reel Refueling: Fuel from the oil tank is filtered, measured, and delivered through the reel hose using a pressure refueling nozzle or gun, into the aircraft’s fuel tanks or other equipment.

– Vacuum Oil Pumping (Defueling): Jet fuel is extracted from the aircraft fuel tanks through the refueling hose, filtered, measured, and returned to the oil tank or other containers.

– Circulation: Circulates and stirs the fuel within the truck’s oil tank.

– Flexible Operation: Offers flexibility with a single-cycle motor and the full capacity of a full trailer.

– High-Quality Oil Tank: Equipped with an aluminum-magnesium alloy tank with a variable cross-section design, promoting the deposition of water and impurities to ensure fuel quality. The manhole cover features a vent valve for anti-overflow and an anti-vortex device.

– Comprehensive Functionality: Fully equipped with various operating functions.

– Advanced Technology: Features pressure control, high and low-level monitoring, and other advanced functions.

– Energy-Efficient and Eco-Friendly: Built on an ISUZU chassis for energy savings and environmental protection.

– Automated Control: Utilizes hydraulic and pneumatic systems for a high degree of automation, making it easy to operate.

– Enhanced Safety: Includes pressure control, high and low-level control, deadman control, interlock operation, and emergency engine shutdown functions.

– Circuit Sampling Capability: Equipped with a circuit sampler.

– Durable Construction: Main steel components and accessories are made from stainless steel or aluminum alloy.

– Compatibility with Aviation Fuels: All seals, O-rings, washers, and other components in contact with oil are compatible with aviation fuels.

– Efficient Drainage: All pipes are designed to be emptied, with pressure measuring points and water discharge plugs at the lowest points.

– Leak-Proof Valves: All oil circuit valves are well-sealed and securely installed, ensuring no leaks under specified pressure and time conditions.

– Pneumatic System Protection: Features a pressure regulator and relief valve in the pneumatic system.

– Night Operation Ready: All instruments, closed-circuit sampling devices, and control panels have adequate lighting for night operations without external light sources.

– Well-Maintained Hydraulic Tank: The hydraulic tank is of sufficient volume, well-filtered, and includes temperature and level indicators. The refueling hose can easily and quickly be released from the reel.

– Interlocking Safety System: The interlocking system is integrated with the chassis brake system, activating under the following conditions:

– Refueling connector not reset correctly.

– Oil inlet guardrail not properly reset.

– Force collector not disengaged.

– Conductive static grounding wire not reset.

– Wheel gear not reset.

– Aircraft fuel tank cover not reset.

– Tank roof channel guardrail not reset.

– Lifting platform not reset.

– Safety and Emergency Measures:

– If any part of the interlocking system is not correctly reset, the interlocking brake is engaged.

– If the Deadman controller fails during refueling, the Deadman override button can be used to continue the operation.

– In emergencies, pressing the engine emergency stop button will shut off the engine and halt refueling. Activating the emergency evacuation switch allows the vehicle to start and leave the area immediately, with alarm lights and sounds activated.

– Equipped with electrostatic grounding coils and wiring clips on both sides, ensuring reliable static conductivity with resistance not exceeding 5 ohms.

– Comprehensive Instrumentation: The refueling truck’s operation panel typically includes the following instruments, all using international standard measurement units:

– Pump inlet vacuum gauge.

– Pump outlet pressure gauge.

– Differential manometer.

– System barometer.

– Reference barometer.

– Hydraulic pressure gauge.

– Pipe pressure gauge.

SPECIFICATION

|

1) General Information |

|

|

1.1 Brand /Model |

ISUZU / CSC5340GJJ |

|

1.2 Date of Manufacturing |

2024 |

|

1.3 Country of Origin |

China |

|

1.4 Truck Unit’s Status |

Brand new |

|

1.5 Overall Dimension (L x W x H) |

11,460 x 2,500 x 3,300mm (approx.) |

|

1.6 Curb Weight |

14,600kg (approx.) |

|

1.7 Max. Speed |

30km/h |

|

1.8 Drive Type |

LHD |

|

2) Fuel Tank |

|

|

2.1 Capacity |

25,000Liters |

|

2.2 Material |

Aluminum alloy |

|

2.3 Bottom Loading |

3″ bottom loading, 2 sets (1 set on each side of the vehicle), China brand |

|

2.4 Aisle, roll-over ledge, ladder, lights |

Factory Standard |

|

2.5 Manhole |

Factory Standard, China brand |

|

3) Refueler Module |

|

|

3.1 Refueling Flow Rate of Single Reel Hoses |

1,200 L/min |

|

3.2 Flow Rate for Defiling Oil/Pumping of Single Reel Hoses |

300L/min |

|

3.3 Flow Rate of Gravity Refueling(over-wing) of Single Reel Hose |

300L/min |

|

3.4 Flow Rate of Loading Oil |

1,500L/min (single hose) 2,500L/min (double hoses) |

|

3.5 Flow meter brand/Type/Accuracy |

ISOIL or Alfons Haar brand standard / Positive displacement with mechanical display / ±0.2% |

|

3.6 Filter Brand |

Velcon or Faudi |

|

3.7 Filtration performance |

Meets the requirements of EI 1581 6th Edition |

|

3.8 Centrifugal Pump Brand |

Gorman Rupp |

|

3.9 Pressure Control Valve |

Maggitt or Alfons Haar |

|

3.10 Hose / Nozzles/ Oil Gun |

1pc 1.5″ 20m reel overwing hose & 1pc 2″20m reel underwing hose & 2pcs 2.5″ 3.5m platform hoses, Hose & nozzles & gun, China brand |

|

3.13 Hose Reel |

Stainless steel, 2sets (1 set for overwing & 1set for underwing), China brand |

|

3.14 Differential Pressure Gauge |

Standard, China brand |

|

3. 15 Overfill Protection |

Standard, China brand |

|

3.16 Sampling Kit & PDG Meter |

Sight glass & Piston type, Standard, China brand |

|

3.17 Control |

Mechanical control |

|

3.18 Cabinet |

Cabinet with refueler module between cabin & fuel tank |

|

3.19 Drain Valve |

Stainless steel auto close spring ball valve, China brand |

|

3.20 Deadman Handle |

Hand switch type, China brand |

|

3.21 BYPASS Valve, Strainer Filter, Deadman Valve, Wafer Check Valve, Venturi, Closed Circuit Tester Jar, Recovery Tank, Pressure Gauges, Drain Valves, Interlock System, Override System, Signal Lights on Control panel, Seamless SS Tubing. |

ALL standard |

Hot Tags: isuzu 25000 liters aircraft refueling truck, China, manufacturers, suppliers, factory, price, quotation, for sale, high quality, high performance

FAQs

Q: Are you a trading company or a manufacturing factory?

A: We are both. We have operated our own factory for over a decade and recently established a trading company to better serve our overseas customers. We welcome your inquiries and factory visits.

Q: What is your typical delivery time?

A: Our delivery time usually ranges from 20 to 50 days after receiving the advance payment. The exact timeline depends on the specific items and quantities in your order.

Q: How do you ensure product quality?

A: We maintain strict quality control standards through our ISO9001:2008 certified system. Additionally, our professional Quality Control team conducts thorough inspections to guarantee the excellence of our products.

Q: What are your payment terms?

A: We require a 40% deposit via T/T (Telegraphic Transfer), with the remaining 60% due before delivery. We will provide photos of the products and packaging for your approval before the final payment.

How are your trucks shipped?

A: Large trucks are typically shipped via RORO (Roll-On/Roll-Off) or bulk cargo ships. Smaller vehicles can be transported in containers. Please contact us for a detailed shipping quotation.

Q: Do you offer customized products?

A: Absolutely. We can design and manufacture customized products to meet your specific requirements.

Q: What kind of after-sales service do you provide?

A: We offer a five-year warranty on our products, covering manufacturing defects. If any quality issues arise within this period, we will repair or replace the product at our expense. For issues outside the warranty coverage, we provide after-sales service at the customer’s expense.