Truck Cab Assebly

Top Strobe Assembly (with Light Bar).

Winch Assembly (2 no.)

Steel Cable(sling).

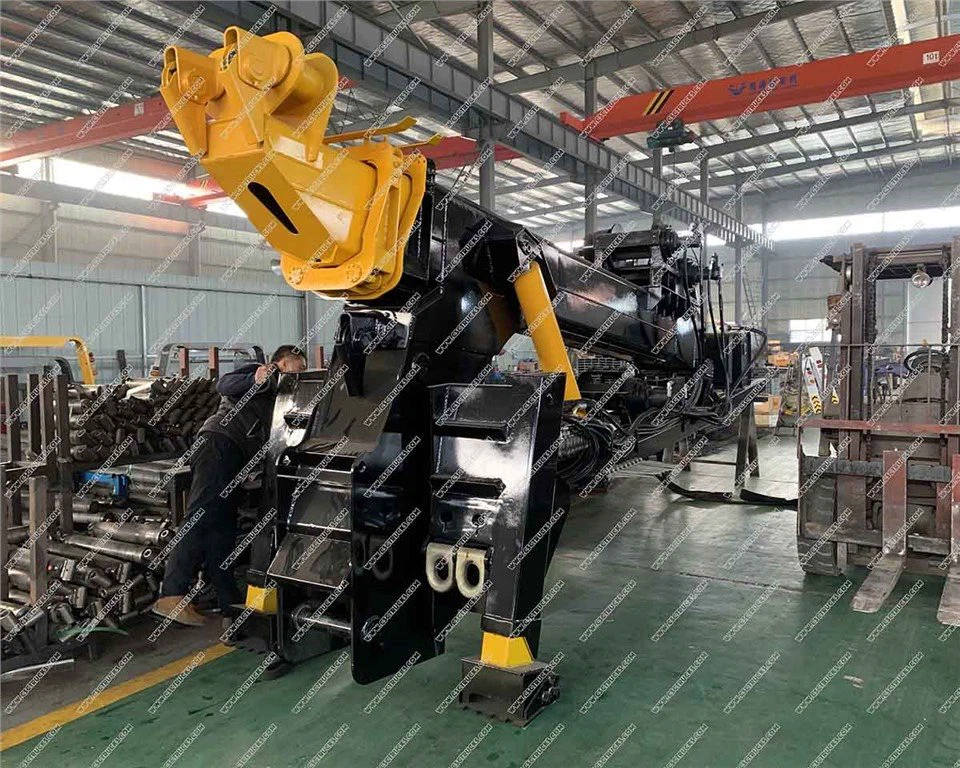

Lifting Boom Assembly

Boom Lifting Cylinders ( 2 No.).

|

|

Description

| Structurer | |||

|

1, Truck Cab Assebly 3, Winch Assembly (2 no.) 5, Lifting Boom Assembly 7, Lifting Boom Bracket. 9, Lifting Hook. 11,Air,ElectricConnects 13,Rear Outrigger. 15,HydraulicSystem. 17,Rotator Assembly (360°). 19,Wheelreceivers. 21, Wired Control. 23, PTO. 25, Front Outriggers 27, Toolbox Body Assembly |

2,Top Strobe Assembly (with Light Bar). 4,Steel Cable(sling). 6, Boom Lifting Cylinders ( 2 No.). 8, Wire Guide Assebly. 10,Underlift System. 12, Tailboard Underlift Controls. 14, Manual Control Panel. 16, Hydraulic Oil Reservoir. 18, Recovery Accessories. 20, Wireless Remote Control. 22, Hydraulic Pump. 24, Front Outrigger Control Panel. 26, PTO Control Switch (cab in control). |

||

| Chassis Recommendations | |||

|

Front axle(s) weight (min) 9 ton Rear axle(s) weight (min) 2 x 10 ton Reccomended Tire size 12R22.5 Clear CA not less than 4353 mm Wheelbase not less than 5100mm |

|||

| Sr.No | Required Specification | Manufacturer Technical Speciication | |

| 1 | Can lifting and towing the Vehicle gross vehicle weight (G.V.W.) not less than 30,000 Kgs. (Without causing the car to be damaged) | Tow Rating 36 ton. Boom Retracted Lifting Capacity (at 60°) 35 ton | |

| 2 | Towing lift kit : working by Hydraulic System and power from engine the vehicle truck by P.T.O. (Power take off) | Underlift : Working by Hydraulic System and power from engine the vehicle truck by P.T.O. (Power take off). 1 no. Cylinder for Tailboard Up down, 2 no. cylinder for Tailboard Fold and Tilt, Underlift Boom Retracted and Extended, Underlift Retracted lifting capacity on forks 15.8 ton. | |

| 3 | Sub frame and Boom , made from High tensile steel (maximum tensile strength is not less than 50,000 psi.) | Sub frame and Boom ,made from High tensile steel maximum tensile strength 600Mpa (87,000psi.) | |

| 4 | Sub frame have length all the vehicle chassis , have the boom attachment point and outrigger attachment point | Sub frame have length all the vehicle chassis , have the boom attachment point and outrigger attachment point | |

| 5 | Have the hook for towing rear the vehicle | Have the hook for towing rear the vehicle | |

| 6 | Boom detail : | Boom | |

| 6.1 | Extension and retracted : telescopic by hydraulic, Extension out reach not less than 5 metres | Extension and retracted : telescopic by hydraulic, Extension out reach 5.48 metres | |

| 6.2 | Lift : Up and down by hydraulic | Lift : Up and down by 2no. Of hydraulic cylinders | |

| 6.3 | Rotation : Left and right not less than 180 angle by Hydraulic | Rotation : 190° CW & CCW by Hydraulic rotator system | |

| 6.4 | Can lifting weight not less than 7,000 kgs , not less than 4 metres by hydraulic, measured from the center of the rear axle to the end of the boom | Can lifting weight (at 60°) 8500kg capacity at extended 4 metres measured from the center of the rear axle to the end of the boom ,by hydraulic 2 no. telescopic cylinders | |

| 6.5 | Have the safety : have the system to protect the hydraulic cylinder collapse. In the event of a hydraulic hose rupture or leakage in every working function. | Safety : have the system to protect the hydraulic cylinder collapse. In the event of a hydraulic hose rupture or leakage in every working function. | |

| 6.6 | Folding boom : The folding boom is located at the end of the lifting boom. Able to tow vehicles with a total weight of not less than 25,000 kg, foldable by hydraulic system,There is a mechanical boom lock to prevent the boom from opening for safety while traveling | Folding boom (Tailboard @ Underlift Assembly ): The folding boom is located at the end of the lifting boom. Tow rating 36000 kg, fold and tilt by 2 no. hydraulic cylinder,There is a mechanical boom lock to prevent the boom from opening for safety while traveling | |

| 6.7 | Extendable boom mounted from a folding boom extresion and retracted With hydraulic system To adjust the distance to suit the lifting and towing It can extend the maximum length of not less than 4 meters, measured from the center of the rear axle to the end of the extended boom holding the bolts for mounting the car wheel support. The pivot point can provide the body while turning and can lift up to a maximum of 1.5 meters from the ground, when the tail is fully retracted, the weight can be lifted at least 7000 kg. | Extendable boom(Underlift Boom @ Underlift Assembly ) mounted from a folding boom extended and retracted by 1 no. of hydraulic cylinder To adjust the distance to suit the lifting and towing.Extended distance to the forks 5.2 meters, measured from the center of the rear axle to the forks. The pivot point can provide the body while turning and can lift up to a maximum of 1.5 meters from the ground, when the tail is fully retracted, the weight can lifted 15800 kg. Fully extended can lift 6800kg. | |

| 6.8 | The boom, folding boom and telescopic boom are constructed of high tensile steel, high tensile strength, not less than 50,000 psi. | The boom, folding boom and telescopic boom are made from High tensile steel maximum tensile strength 600Mpa (87,000psi.) | |

| 7 | Winch detail : | Winch | |

| 7.1 | Planetary winch Working with hydraulic system Installed on the boom lift not less than 2 sets, capable of as follows | Planetary winch Working with hydraulic system Installed on the boom lift 2 sets, capable of as follows | |

| – Max pull on 5 layer : not less than 7,000 kg. | – Max pull on 5 layer : 7,000 kg. | ||

| – Max pull on 1 layer : not less than 15,000 kg. | – Max pull on 1 layer : 15,000 kg. | ||

| – have free pulling (Releasing) and Multi dise brake | – Have free pulling (Releasing) and Multi dise brake (air operated) | ||

| – Sling : Diameter not less than 20 mm. , Length not less than 30 metre and hook | – Sling : Diameter 20 mm, Length 45 metre and hook | ||

| – Working pressure (Hydraulic oil) not less than 200 bar | – Working pressure (Hydraulic oil) not less than 200bar | ||

| – Flow rate hydraulic oil : 60 litre/minute | – Flow rate hydraulic oil : 60 litre/minute | ||

| – Hydraulic motor cylinder capacity (motor displacement) not less than 80 cc. | – Hydraulic motor cylinder capacity (motor displacement) not less than 80 cc. | ||

| – have hydraulic winch 2 set , meet the ISO 9001 standard (attached cataloge and certification document) | – Have hydraulic winch 2 set , meet the ISO 9001 standard | ||

| 8 | Controller system : | Controller System | |

| 8.1 | have the controller can control the wrecker , towing and outrigger : installation inside the tool box (compartment) have the door and lock | Control Panel: Have the controller can control the wrecker , towing and outrigger : installation inside the tool box (compartment) have the door and lock ,Tailboard Underlift Controls | |

| 8.2 | have the safety : have the system to protect the hydraulic cylinder collapse. In the event of a hydraulic hose rupture or leakage in every working function | Safety Device : have the system to protect the hydraulic cylinder collapse. In the event of a hydraulic hose rupture or leakage in every working function | |

| 8.3 | have wireless remote control : 1 unit and wire remote control : 1 unit can control not less than 10 metre | Wireless Remote Control : 1 unit and wireless remote control : 1 unit wired control cable length 12 metre. | |

| 9 | Outrigger : | Outrigger | |

| 9.1 | Outrigger working with Hydraulic , freedom the control left and right , have the to protect the hydraulic cylinder collapse. In the event of a hydraulic hose rupture or leakage in every working function | Outrigger working with Hydraulic , freedom the control left and right , have the device to protect the hydraulic cylinder collapse. In the event of a hydraulic hose rupture or leakage in every working function | |

| 9.2 | Front outrigger : A TYPE installation with sub frame , can extendable side car suitable for working | Front outrigger : A TYPE installation with sub frame , can extendable side car suitable for working. ( A TYPE front outrigger is old style will required much more space in subframe in cab to rear space , manufacturer suggest H TYPE front outrigger.) | |

| 9.3 | Rear outtrigger : installation with sub frame , can extendable suitable for working | Rear outtrigger :H TYPE installation with sub frame , can extendable suitable for working | |

| 9.4 | There are 2 types of support leg end: tooth type and flat floor type. Which can be adjusted as appropriate for use | Rear Outrigger Spade Attachments: There are 2 types of support leg end with tooth type and flat floor type. Which can be adjusted as appropriate for use. | |

| 10 | Towing equipment : | Recovery Accessories (Towing Equipment ) | |

| 10.1 | 1 towbar with a hole for inserting a fork to lift | 1 towbar (crossbar) with a hole for inserting a fork to lift | |

| 10.2 | Different sizes of fork to raise the axle or chassis. | 3 sets of Different sizes of fork to raise the axle or leaf spring. 1 set of Fork Adaptor | |

| 10.3 | Wheel support for 1 set of passenger cars can hold a minimum of 1500 kg. | Wheel support for 1 set of passenger cars can hold a minimum of 1500 kg.( not clear what is this? is a wheel trolley as following photo) |

|

| 10.4 | Wheel assist devices for towing in case the wheels can not turn, including an attachment of 1 set |

1 set of Wheel assist devices for towing in case the wheels can not turn, including an attachment.( not clear what is this? is 19, Wheel receivers as following showed?) |

|

| 10.5 | Equipped with a 2-axis car balancing device, it can adjust the balance level up to + -20 degrees while the hydraulic system is working. If the car is tilted more than required The balance aid kit will sound an alarm. For the safety of machines and staff operating. | Equipped with a 2-axis car balancing device, it can adjust the balance level up to + -20 degrees while the hydraulic system is working. If the car is tilted more than required The balance aid kit will sound an alarm. For the safety of machines and staff operating. | |

Hot Tags: skid mounted wrecker towing truck 30 ton, China, manufacturers, suppliers, factory, price, quotation, for sale, high quality, high performance

FAQs

Q: Are you a trading company or a manufacturing factory?

A: We are both. We have operated our own factory for over a decade and recently established a trading company to better serve our overseas customers. We welcome your inquiries and factory visits.

Q: What is your typical delivery time?

A: Our delivery time usually ranges from 20 to 50 days after receiving the advance payment. The exact timeline depends on the specific items and quantities in your order.

Q: How do you ensure product quality?

A: We maintain strict quality control standards through our ISO9001:2008 certified system. Additionally, our professional Quality Control team conducts thorough inspections to guarantee the excellence of our products.

Q: What are your payment terms?

A: We require a 40% deposit via T/T (Telegraphic Transfer), with the remaining 60% due before delivery. We will provide photos of the products and packaging for your approval before the final payment.

How are your trucks shipped?

A: Large trucks are typically shipped via RORO (Roll-On/Roll-Off) or bulk cargo ships. Smaller vehicles can be transported in containers. Please contact us for a detailed shipping quotation.

Q: Do you offer customized products?

A: Absolutely. We can design and manufacture customized products to meet your specific requirements.

Q: What kind of after-sales service do you provide?

A: We offer a five-year warranty on our products, covering manufacturing defects. If any quality issues arise within this period, we will repair or replace the product at our expense. For issues outside the warranty coverage, we provide after-sales service at the customer’s expense.